Eley Metrology Limited

ELEY Metrology Computerised Height Gauges

Eley Metrology Computerised Height Gauges come with on-board micro-processor, key pad and integral printer. They are unique in that only one handed operation is required to probe internal and external diameters making them easily the fastest measuring machines available.

The key pad is easy to understand with many features called up with a single key press. With the addition of a digital probe, features such as angle, squareness and straightness are easily measured with a graph of the results printed on completion of the scan.

There is a 2D feature that allows full 2 dimensional measurements to be taken if the work can be fixed to an angle plate or cube and rotated through 90° to obtain X and Y co-ordinates.

Pitch Circle Diameters and feature positions can then be printed out or simply displayed in rectangular or polar co-ordinates. An alignment feature is available to enable aligning and recalling positions relative to any feature you wish.

Eley Metrology manufacture a full range of accessories for their Microvertex Height Gauges including surface plates and accessories.

The “NEW VERTEX” VMS Range…

Achieving new heights of PRECISION.

Eley Metrology GOLD and SILVER VMS 800 range:

| Measuring Range | - 800mm with Duel probe holder |

| Resolution | - 0.0005mm |

| Accuracy | - 1.8 micron + L/400mm |

| Measuring system | - Incremental scale |

| Squareness & Straightness | - Max error front = 3.5 Micron / Max error side = 5.0 Micron |

| Measuring force | - Constant at 0.4N under motor control |

| Orbital display | - LCD alpha/numeric, multilingual |

| Program Storage | - Intergral/Remote |

| Air Pressure | - In built pump (Variable) |

| Power Supply | - Battery powered/Mains adaptor |

| Weight | - 30Kgs |

| Data output | - RS232 or Bluetooth |

| Carriage Lock | - Yes |

| Interface connections | - 2 x RS232C |

| Counter Balance Lock | - Yes (For Transit) |

Standard sizes available are 800mm, 1000mm and 1300mm

| GOLD range Standard Features include: | |

|

|

SILVER range Standard Features include: |

|

|

|

To see Video click on - http://vimeo.com/13358377

ELEY CMMs

With more than 30 years experience of manufacturing metrology products, ELEY Metrology are proud to be the leading UK independent manufacturer of coordinate measuring machines.

With more than 30 years experience of manufacturing metrology products, ELEY Metrology are proud to be the leading UK independent manufacturer of coordinate measuring machines.

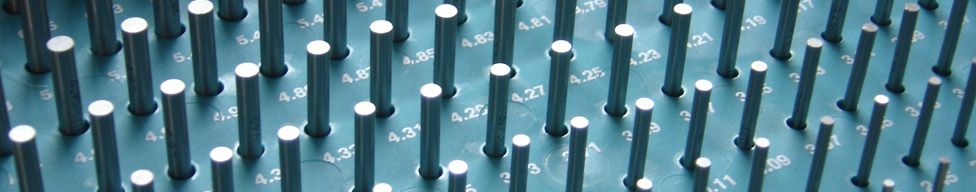

With high precision manufacturing techniques, and constructed from hand lapped granite, ELEY CMMs are the only machines that don’t require software ‘error mapping’. Available in a standard measuring range of sizes from 500x400x400 up to 3000x1800x1200mm, these CMMs are capable of scanning with probe or laser head. Larger sizes are available on request, and indeed special designs can be produced, such as the groundbreaking LBM (Long Bore Machine) with a 2 metre long measuring arm and in constant use at a leading aerospace companies.

With high precision manufacturing techniques, and constructed from hand lapped granite, ELEY CMMs are the only machines that do not require software error mapping. CMM bridges that are made of aluminium offer no benefit to the end user with a coefficient of expansion almost 4 times that of granite, the only issue is how to try and make aluminium CMMs accurate. The only answer is to use software error mapping.

With high precision manufacturing techniques, and constructed from hand lapped granite, ELEY CMMs are the only machines that do not require software error mapping. CMM bridges that are made of aluminium offer no benefit to the end user with a coefficient of expansion almost 4 times that of granite, the only issue is how to try and make aluminium CMMs accurate. The only answer is to use software error mapping.

Almost all CMM software packages have measurement algorithms that have been certified by a national accreditation body such as PTB; NO such accreditation of vendor error map algorithms exists. Most manufacturers of aluminium CMMs also "lock-up" their error maps to prevent access. Maybe they are embarrassed by the magnitude of errors they are compensating for or maybe they mandate that the calibration pounds (£££'s) spent annually by CMM users belong to them as they refuse to allow others to adjust 'their maps' to correct for CMM geometry adjustments that occur with aluminium structures over time.

| Downloadable PDF file - Project FitIt Software - 113KB Right Click to begin download. |

| Downloadable PDF file - True Measure 3 CMM Software - 107KB Right Click to begin download. |

| Downloadable PDF file - True Shape CMM Software - 107KB Right Click to begin download. |

LIST OF BENEFITS FOR THE ELEY RANGE OF CMMs

- Built with 100% hand lapped granite for ultimate stability and strength

- X-axis is a granite wall or ‘riser’ that makes that axis ultra-stable

- On it is a V-Flat guide way, as used by machine tool companies and renowned for producing the best accuracy as they sit on a triangular point

- X-axis ‘V-Flat’ guideway has air bearings on all 4 sides, thus fulfilling metrological principles

- Y-axis bridge is a twin beam; with the Z-axis spindle located centrally between them, and perfectly balanced, it is also mounted on 3 individual steel ball jacks, so it is ‘kinematically’ mounted and free from stress

- The Z-axis assembly floats on air bearings that are both in top and underneath the Y-axis bridge, to prevent ‘lifting’ it is also kinematically mounted on 3 ball jacks so it is free from stress in the rest of the machine.

- The Triangular spindle, with its ‘3-point’ location system provides great benefits for accuracy and stability

- Machine covers made from anodised aluminium cover the whole of the axis, with ‘blinds’ for accessing the beam and scale. This maximises the protection for the scales etc.

Certified in our own UKAS accredited lab to ISO 10360-2.

ELEY were the first CMM Company in the world to attain ISO 10360.