The Axiom too range of reasonably priced high performance CNC CMM's are ideal for volume production. The high quality shop floor design features Aberlink's easy-to-use software plus the flexibility of touch probe and non-contact inspection using the optional Aberlink CMM camera. A manual version of this machine is also available.

KEY FEATURES

- Aberlink's easy-to-use measurement software (now standard on many OEM systems)

- Shortest learning curve of any similar system - 1.5 days without prior CMM experience

- Smallest overall footprint of any equivalent size CMM

- Choice of sizes ranging from 600mm to 1500mm

- Suitable for the quality audit room and workshop environment

- High tech air bearing design incorporating the latest materials technology

- Anti-vibration protection from local machine tools as standard

- Ergonomic touch sensitive 3D joystick and variable speed control

- Comprehensive range of probing options and accessories

- Temperature compensation option for unstable environments

- Optional CMM camera system option for non-contact inspection

- Optional Laser Scanner option for non-contact inspection

- Free stylus change rack with every motorised probe head upgrade

The Zenith too range of CMM's are a cost effective metrology solution for big and heavy parts. The high quality shop floor design features Aberlink's easy-to-use software plus the flexibility of touch probe and non-contact inspection using the optional Aberlink CMM camera.

KEY FEATURES

- Aberlink's easy-to-use measurement software (now standard on many OEM systems)

- Shortest learning curve of any similar system - 1.5 days without prior CMM experience

- Smallest overall footprint of any equivalent size CMM

- Choice of sizes ranging 1000mm to 3000mm

- Suitable for the quality audit room and workshop environment

- High tech air bearing design incorporating the latest materials technology

- Anti-vibration protection from local machine tools as standard

- Ergonomic touch sensitive 3D joystick and variable speed control

- Comprehensive range of probing options and accessories

- Temperature compensation option for unstable environments

- Optional CMM camera system option for non-contact inspection

- Optional Laser Scanner option for non-contact inspection

- Free stylus change rack with every motorised probe head upgrade

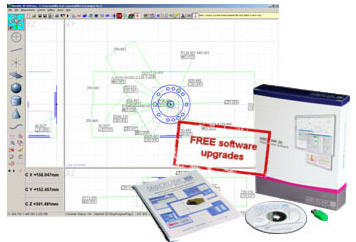

ABERLINK3D

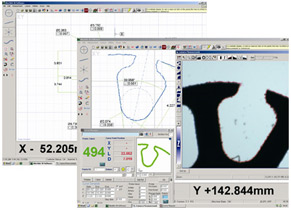

Aberlink 3D is an innovative software package designed for manual and CNC CMM's, portable arms, vision systems, video machines and profile projectors and is the software of choice for numerous OEM systems.

Now popular throughout the world, Aberlink's revolutionary measurement software provides the user with a powerful, yet easy to use, state-of-the-art user interface. The software's unique interactive graphical interface offers a more satisfying user experience, substantially increases component through-put and vastly decreases the learning period of new users.

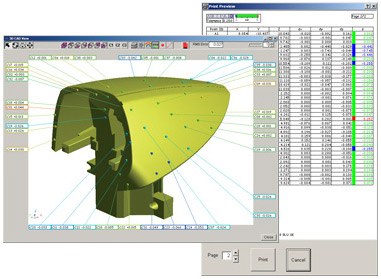

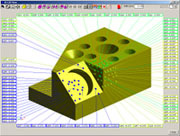

CAD COMPARISON

The Aberlink CAD Comparison software module enhances Aberlink 3D with the capability to measure (compare) surfaces directly to a CAD model of the part - often the only way to measure complex parts.

Powerful alignment routines allow the CAD model to be used to create a best-fit datum, and colour report templates provide the output formats required to analyse complex surfaces.

|

|

|

CAD FORMATS

|

REPORT FORMATS

|

|

ALIGNMENTS

|

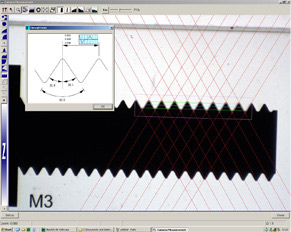

VISION SOFTWARE

The Aberlink Vision Software module enhances the capability of Aberlink 3D with a set of powerful vision measurement tools - now you can use the same software with your touch probe and non-contact system.

Measure geometric features, scan profiles and inspect threads using high-accuracy edge detection and high-speed optical scanning. Programmatically control the camera and light settings plus simulate cross hairs and overlays.

|

SCREEN OVERLAYS

|

THREAD INSPECTION

|

|

PROGRAMMING TOOLS

|

FEATURE INSPECTION

|

|

OPTICAL SCANNING

|

![]()

|

|