services

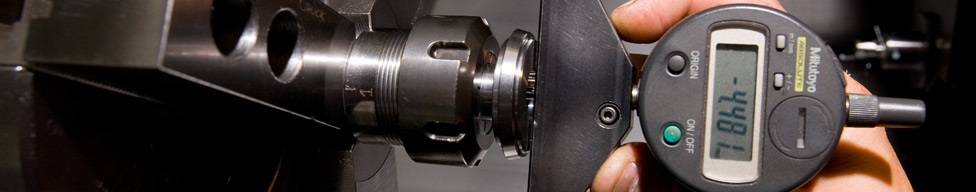

We have total control over product quality and delivery as all processes are carried out in-house to our exacting quality standards. With the support of our in-house measurement facility and the Metrology Group's IANZ accredited calibration and measurement laboratory, conformance to customer quality requirements is assured. Certificates of conformance with full traceability to National or International Standards is offered if required.

Our capabilities

- Manufacturing and Production Engineers on a global basis

- Milling / Turning

- CNC Milling - 3,4 and 5 Axis Simultaneous

- CNC Turning

- Deep Hole Drilling

- Cylindrical Grinding OD/ID

- Surface Grinding

- Thread Grinding

- Spark Erosion / Wire Cutting

- Honing

- Lapping

- Heat Treatment

Our Services

- Contract Machining of interchangeable plastic mould components to your specifications

- Precision grinding and lapping of forces, cores, strippers etc

- Production manufacturing of aerospace components & sub assemblies

- Manufacture of jet engine assembly and support tooling

- Thread Grinding - CNC Machining - Spark Erosion

- Gauge, Tool & Fixture manufacture and refurbishment

- Independent QA certification of components to ensure all items manufactured are fully interchangeable, meeting or exceeding specifications

- Full CAD suite

- Manufacturers of SAE ARP 4162 Proving Rotors and Test Weights - certification directly traceable to NIST USA.

Click here to Download Metal Tech Engineering Company brochure